Objective

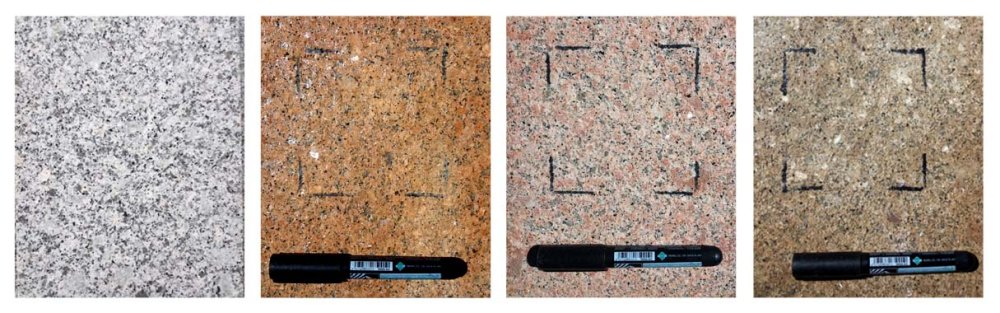

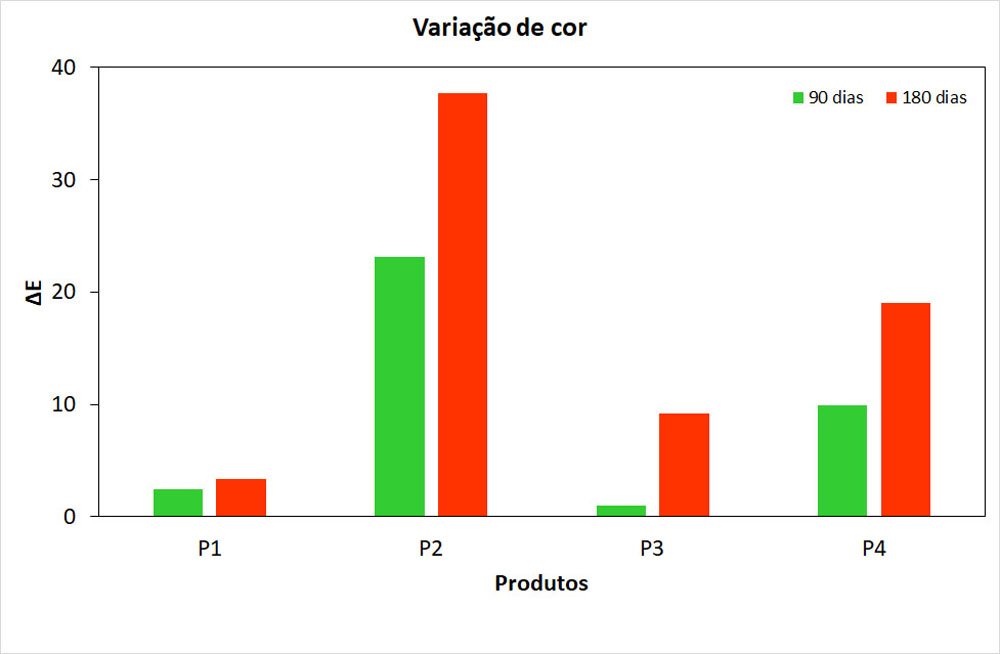

The investigation carried out sought to identify the best oxidation/color techniques for various varieties of Portuguese gray granites.

The products used make it possible to obtain granites with yellow/brown color, similar to the natural color of oxidized granites.

In addition to these obtained colors, it is also possible to obtain pink tones.

The process used allows for a gradation in the intensity of the color to be obtained.